Eco Ultra

Eco Ultra® is the new-generation economical solution for wrapping round and square bales.

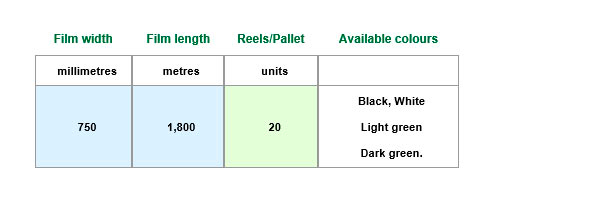

The Eco Ultra® agri-stretch film was developed to provide exceptional performance when wrapping bales. The rolls have 20% more metres, compared to a standard 750 mm film (1,800 m as opposed to the traditional 1,500 m).

This additional length allows wrapping up to 6 more bales per rolls, optimising and reducing the wrapping costs for the contractor by 20%.

Time is also saved, because less rolls have to be changed at the end of the day, and less machine stops.

A simple calculation, dividing the price of the roll by the number of bales that you get with Eco Ultra®, will show you the film’s excellent cost-profit relation, which is hard to beat by other brands.

Due to its 20% cost benefit, Eco Ultra® is the stretch film offering the best value for money in the market.

Eco Ultra® is a co-extruded film in 7 layers, which is also manufactured with special latest-generation polyethylene co-polymers that provide excellent resistance to impacts and to tears (higher than the one from standard films). The formulation chosen for Eco Ultra® makes it ideal for high-performance wrapping of silage fodder bales.

Eco Ultra®: 20% more meters per roll = 20% more bales per roll = 20% more value!

GENERAL DIMENSIONS

COLOURS: Black, white and green (light and dark) PACKAGING: contractor packaging (without boxes).

CHARACTERISTICS

1- Manufactured using the highest quality raw materials available in the market:

Providing optimal mechanical properties for stretching, resistance and reliability.

2- Blow extrusion Technology.

Offering an ultra-resistant film when stretched both in transverse and longitudinal direction.

3- 7-layer co-extruded blown films.

Much better resistance for the same thickness compared to a 5 layer film.

4- Excellent adhesive strength.

To keep air and water-tightness between the layers of film and achieving an optimal silage fermentation.

5- Minimum gas permeability.

Special barrier formulation to reduce CO2 loss and O2 intake.

6- Improved elasticity.

Minimizing breakings and tearing during the pre-stretch process of the film on the bale wrapper.

7- Superior elastic memory.

Bales remain tightly packed for up to a year after wrapping.

8- High resistance to perforation.

To withstand piercing dry stalks and angular corners of square bales.

9- Automatic thickness control.

A 22 micron (=0.022 mm thickness) should not have weak spots and must be of uniform thickness throughout.

10- Good opacity and colour density.

Offers greater protection from sunlight thus improving fermentation.

11- UV Stabilized 1 year.

Can resist outdoors exposure up to one year in southern Europe or in forage areas of Australia.

12- Recyclable high-resistance plastic or cardboard cores.

Weather resistant, without collapsing as occurs with some cardboard cores.

This film range is developed to be used into all types of bale wrappers and with all kind of bales: round, square, minibales, in-line wrapping, combi, etc.

In Aspla we are committed to a continuous improvement of our products, thus offering solutions to meet the changing needs and new challenges of the agricultural market. To keep moving forward, we engage into an ongoing process of improving performance and efficiency with a long term view. This view is combined with investments into state-of-the-art technologies to achieve the highest standards in silage wrapping.

FOR MORE INFORMACIÓN:

Aspla's factory at Torrelavega, Cantabria.

Aspla's factory at Torrelavega, Cantabria.

The Armando Alvarez Group of Companies is currently the largest Spanish converter of plastic polyethylene film..

Closer to the future

Our experience along with commitment to quality and technology has made us leader in the European and world markets.